Minimizing mercury emissions

Germany

The challenge

A municipal waste incinerator with a capacity of 700.000 t/ year operates 4 lines. The flue gas cleaning process of each line consists of:

- spray dryer (using wet scrubber effluents)

- electrostatic precipitator (ESP)

- wet scrubber

- SCR

- and a tail end fabric filter operated as ‘police’ filter.

The Sorbacal® Micro sorbent, consists of lime-based materials, special minerals, activated carbon and doping agents. It is used at the ‘police filter’ to secure the emission limits both for acid gases and micropollutants. The challenge was to further reduce the emission of mercury preferably by optimizing the sorbent used at the ‘police’ filter.

The Lhoist solution

Based on our experience and the specific customer requirements, Lhoist proposed a blended sorbent including a high-quality activated carbon and efficient mercury (Hg) removal doping agents.

The ‘Hg-optimized’ blend was produced in one of Lhoist’s blending units and tested at the waste incinerator using the existing silo and dosing equipment without changing the sorbent feed rate. The existing Hg clean gas measurement system was used to check the Hg removal performance of the new blended sorbent.

The benefits

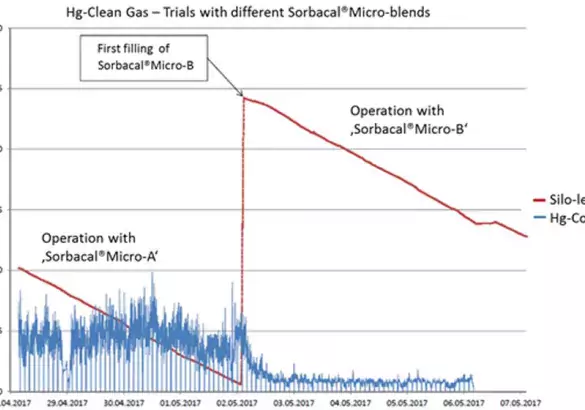

The trial demonstrated that the new Hg-optimized blend enabled a decrease in Hg clean gas values from currently 5 - 7 µg/Nm³ down to 1 – 3 µg/Nm³ without changing the sorbent feed-rate. Optimizing the sorbent composition was not only effective in further reducing the already low Hg emissions, it also allowed the customer to use its existing equipment, thus reducing the cost of a new or reconfigured dosing system.

Lhoist has continued to work closely with this customer for 3 years to optimize the feed rate and if necessary, fine tune the composition of the blend.

Decreasing Hg clean gas daily values

The graph shows the continuously monitored Hg clean gas values from one line of the waste incinerator as well as the silo level of one sorbent silo. After the first filling of the silo with the new ‘Hgoptimized’ Sorbacal Micro blend A, Hg clean gas daily values went down from previously 5 - 7 µg/Nm³ to 1 - 3 µm/Nm³. The current Hg emission limit is 10 µg/Nm³. The range of half hour peak values went down from previously 2 - 9 µg/Nm³ to 1 - 3 µg/Nm³.