Carbon Capture, Utilization and Storage (CCUS)

Solutions for a low-carbon future

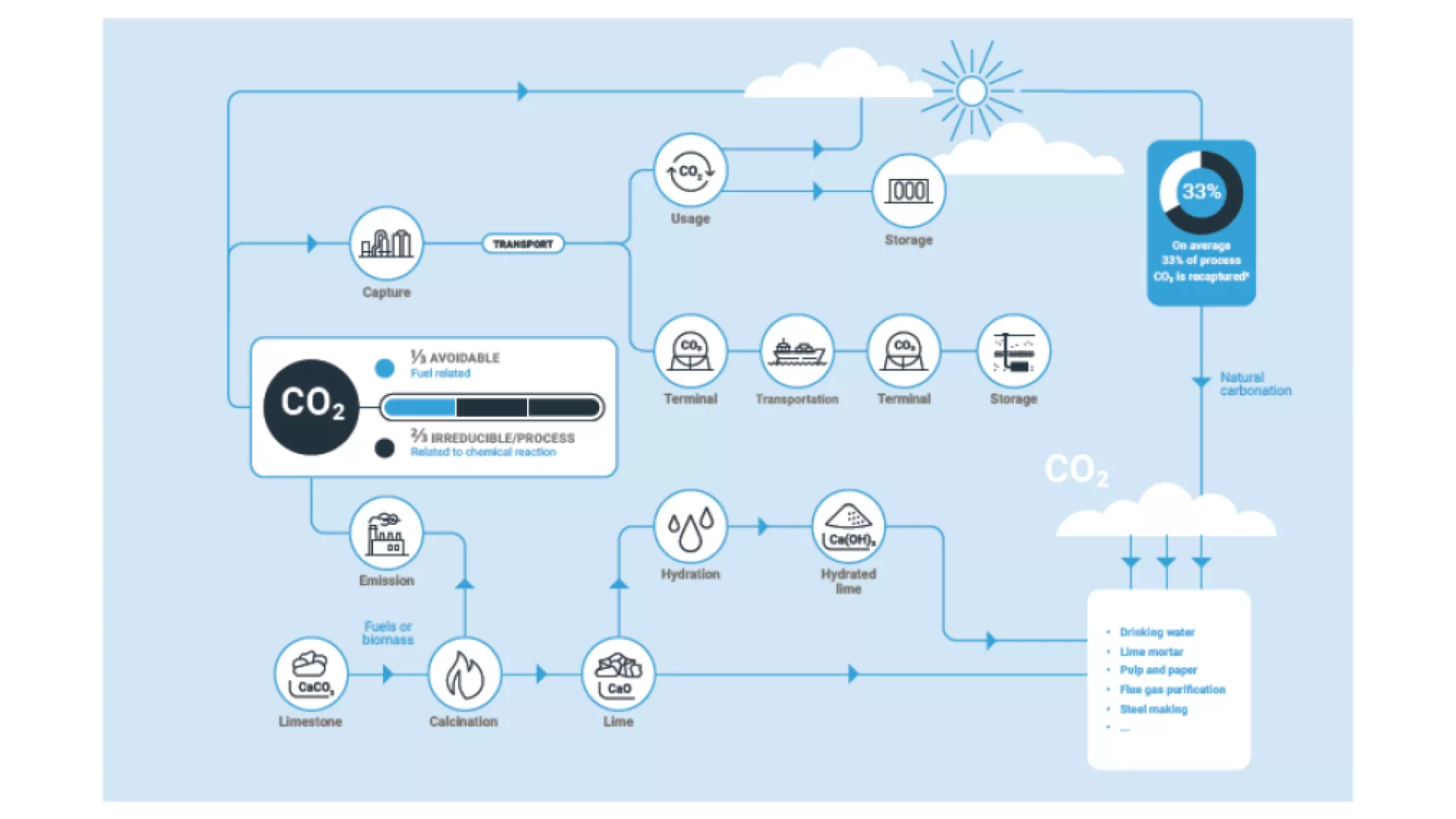

Climate change has been a longstanding concern, and awareness of the harmful effects of greenhouse gas emissions, particularly carbon dioxide (CO2) released through human activities like the burning of fossil fuels, continues to grow. About 40 billion tons of anthropogenic CO2 are emitted every year, and lime production represents about 1% of these global CO2 emissions.

To mitigate our environmental impact, we are continuously developing and implementing various solutions across our sites, as we work towards a low-carbon production process.

Our emissions come from two major streams:

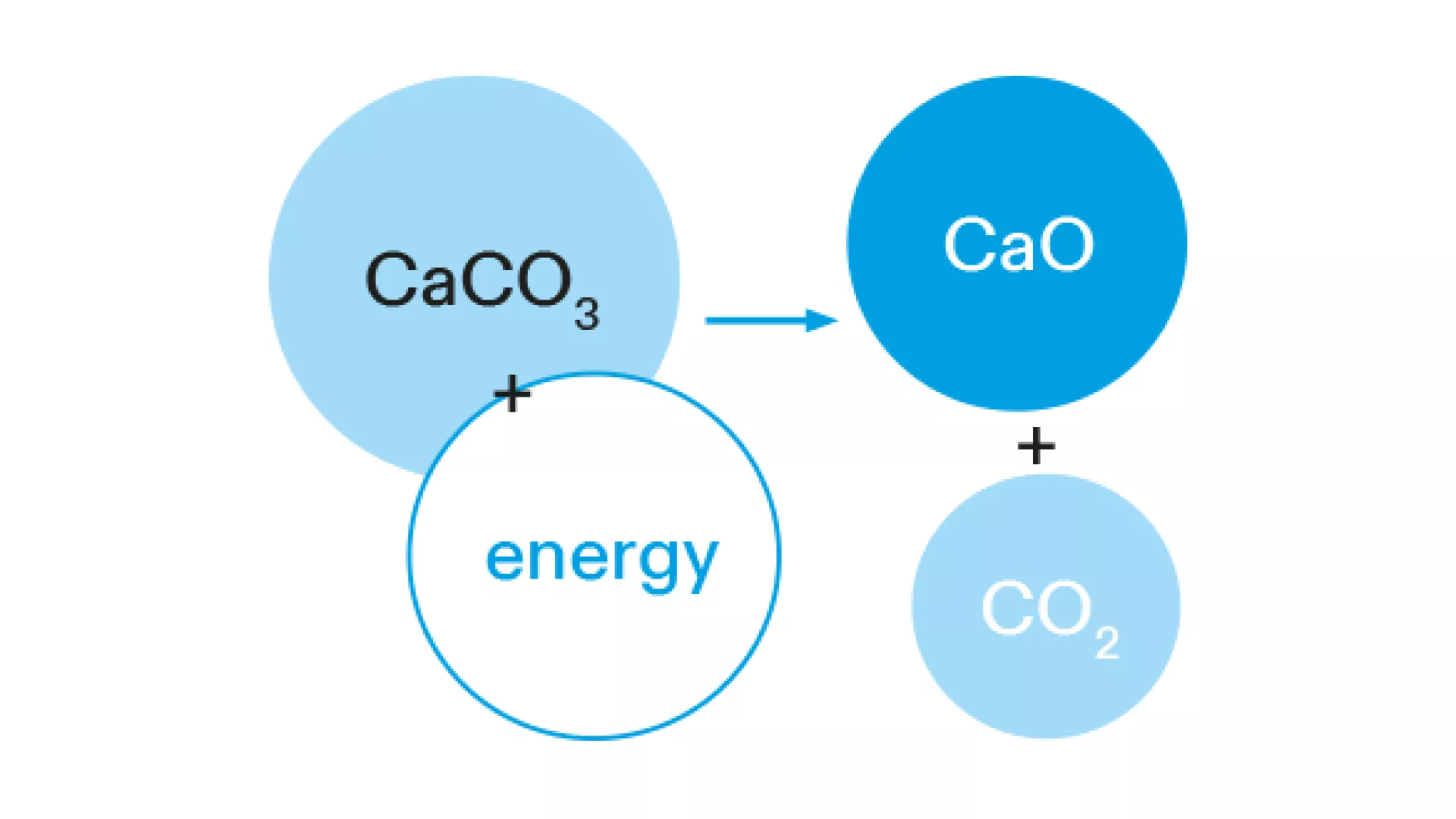

- Combustion emissions as the result of fuel burning, including fossil fuel, to heat kilns. We can significantly reduce these emissions by switching to more efficient kilns or using low-carbon or carbon-neutral fuels (e.g. sustainable biomass) and even renewable electricity in the future.

- Process emissions come from the chemical conversion of limestone into lime. The lime manufacturing process requires a substantial amount of energy to thermally calcine limestone to calcium oxide, generating CO2 emissions as a by-product. We cannot avoid these emissions.

Carbon capture and utilization

Carbon capture and utilization (CCU) refers to a range of applications through which CO2 is captured and used either directly (i.e. not chemically altered) or indirectly (i.e. transformed into other products). Some new uses are being investigated, such as making CO2-based synthetic fuels, chemicals, and building aggregates. In most cases, the CO2 needs to be captured, concentrated, and purified to enable its transportation and use.

Our ambition to actively develop CCU technologies that are essential to the sustainability of our industry is illustrated by the co2ncreat project. This new process replaces the cement and natural aggregates used in traditional building blocks with by-products from the steel industry and CO2 captured from lime manufacturing.

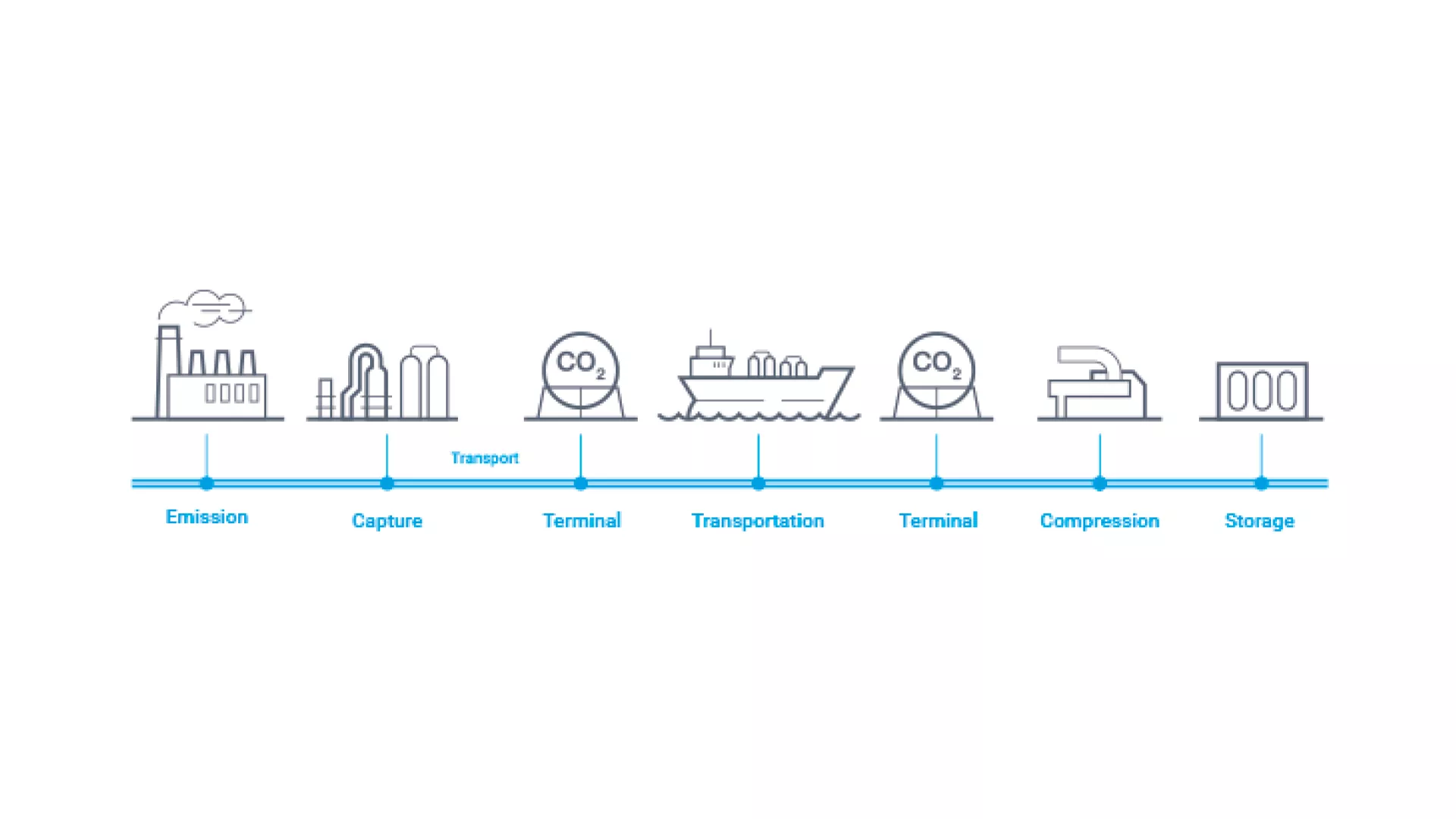

Carbon capture and storage

Carbon capture and storage (CCS) is considered as one of the most effective options for reducing significant atmospheric emissions of CO2 from human activities. In practice, it would most likely be applied to large sources of unavoidable CO2 emissions, such as large industrial processes. CCS uses technology to collect and concentrate the CO2 produced, transport it to a suitable location, and store it away from the atmosphere. Potential storage methods include injection into underground geological formations, while alternative storage on the surface can also be considered.

We are collaborating with a diverse set of partners to engineer innovative CCS solutions such as the CalCC project at our Rety plant in France, the EVEREST project in Flandersbach in Germany and the GLOBE project in Marche-Les-Dames.

Decarbonization of the lime cycle

It is also important to acknowledge the role of lime as a carbon sink. Many common applications of lime rely on its ability to absorb CO2 from the atmosphere or an industrial source (80-92% lime mortar, 32% flue gas purification, 93% pulp and paper, 5-28% steel making, and 100% drinking water). A 2020 study1 showed that within the first year, lime absorbs on average a third of the amount of all process CO2 emitted during production. This presents the potential for using lime as a carbon sink.

1Grosso M., Biganzoli L., Campo F. P., Pantini S., Tua C. 2020. Literature review on the assessment of the carbonation potential of lime in different markets and beyond. Report prepared by Assessment on Waste and Resources (AWARE) Research Group at Politecnico di Milano (PoliMI), for the European Lime Association (EuLA). Pp. 33