CalCC

Project Summary

First industrial-scale carbon capture for lime production integrated with transport of CO2 to coastal hub and shipping to geological storage in the North Sea

The CalCC project would showcase a pathway for decarbonization in the European lime industry. The project aims to capture and permanently store the CO2 emitted during lime production at the Lhoist Group’s Réty site in France. This innovative project would cover the full CO2 value chain: capture, transport, liquefaction, shipping, and offshore geological storage.

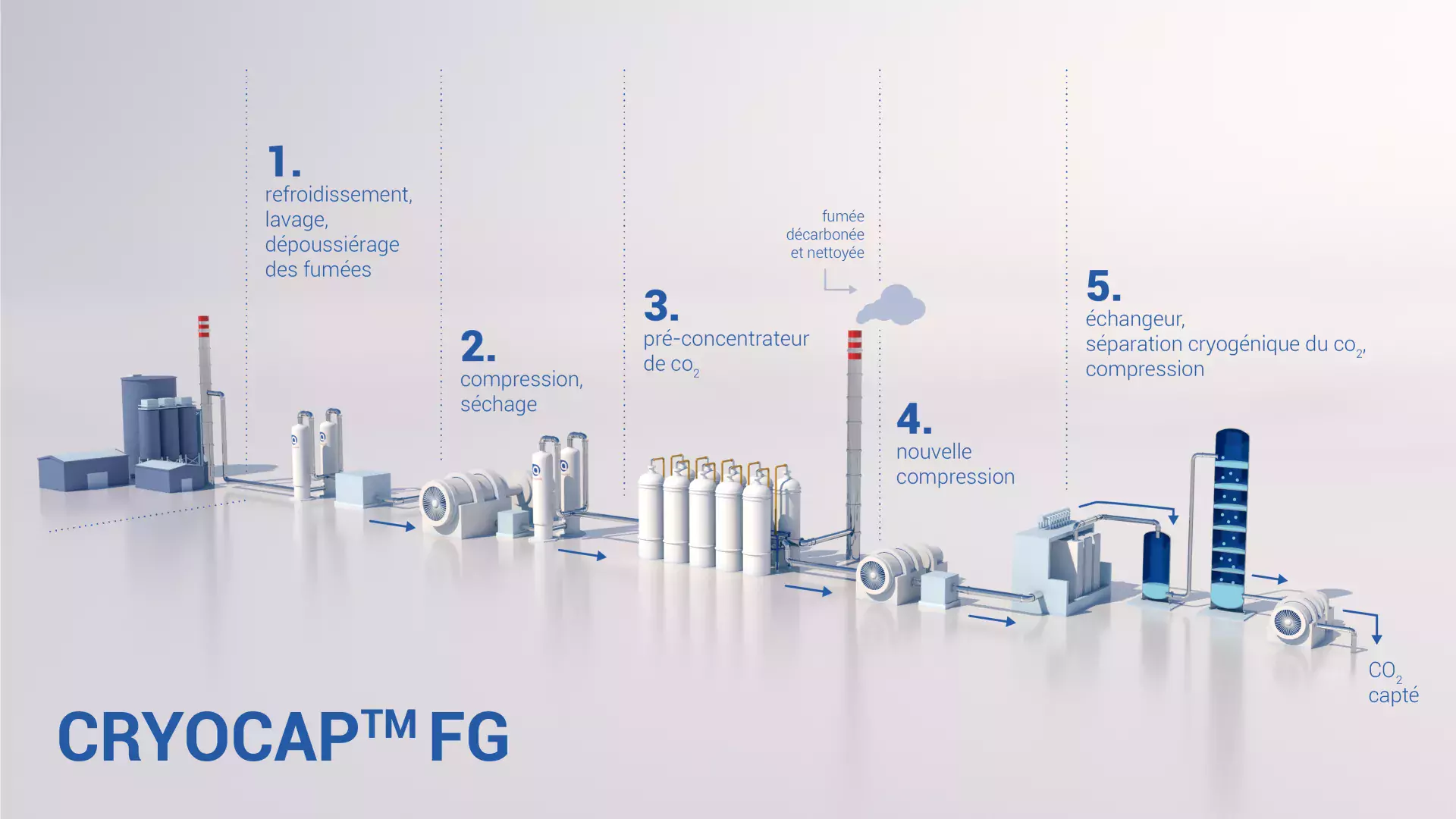

For the carbon capture aspect of the project, Air Liquide would build the first Cryocap™ FG unit in a lime plant at an industrial scale. The Cryocap™ technology uses cryogenic temperatures to separate gases and creates a very high-purity CO2 stream needed for CO2 transport and geological storage.

More than 80%

of the CO2 generated by the plant would not be emitted into the atmosphere

Thanks to this project, Lhoist would be able to reduce the CO2 emissions of the plant in Réty by more than 600,000 tons per year starting in 2028. This is equivalent to the annual emissions of about 55,000 households in France.

2023

Project starting date

2028

Planned date of entry into operation

Réty

France

The first low-carbon intensity lime on the market

The lime industry is one of the “hard-to-abate” industries, as lime production generates CO2 from the decomposition of limestone. These so-called “process emissions” cannot be avoided by switching to zero-carbon fuels.

This first-of-its-kind project would support local and other European lime users from various industries, such as water treatment, chemicals, paper, and steel manufacturing, in their path to carbon neutrality, by providing the first low-carbon lime on the market. Leveraging its know-how and unique expertise in CO2 capture technologies, Air Liquide would build and operate a unit of its innovative and proprietary Cryocap™ FG (Flue Gas) technology. This would capture and purify 95% of the CO2 from Lhoist’s existing lime production unit in the Hauts-de-France region. The cryogenic carbon capture technology is 100% electrical and would be used for the first time in Europe to decarbonize the lime sector.

The deployment of a low-carbon industrial ecosystem

The CalCC project would be a further step in creating a low-carbon industrial ecosystem in the broader Dunkirk area. The CO₂ captured would be transported by pipelines built and operated by Air Liquide to a new CO₂ terminal in the West Port of Dunkirk, in the proximity of the LNG terminal. This new terminal, which would be built and operated by Air Liquide and Dunkerque LNG, would receive and liquefy CO₂, for shipment to permanent storage sites in the North Sea. Designed to be open to industrial companies in the region for the transport and shipment of CO₂, this terminal would open the way to other CO₂ capture and sequestration projects in the Dunkirk basin.

A solution to support the EU’s carbon neutrality objective

This innovative project would bring together all the elements of the carbon capture and storage (CCS) chain, solving potential interface issues and demonstrating the full value chain for the first time on a lime plant. The project will pave the way for other emitters, as it shows a high scalability potential on existing plants both at the sector level (cement and lime industry) and on an economy-wide level across sectors and countries. The CalCC project would share its experiences to support industries in their efforts to contribute to the EU’s objective of achieving climate neutrality by 2050.

Important project milestones

- European Innovation Fund grant agreement signed, marking a significant step for the project with the European Climate Infrastructure and Environment Executive Agency (2023).

- Progress on FEED (Front-End Engineering Design) and permitting steps, including environmental studies and authorization application preparations, achieved by Lhoist and Air Liquide.

" I am particularly thrilled to contribute to this exciting adventure to develop the CalCC project. Participating in this journey to develop the worldwide first low-carbon lime plant on an industrial scale is both inspiring and challenging. "

CO2 Application Director - Lhoist Group

More on the CalCC project

Contact

Coordinator:

Chaux et Dolomies du Boulonnais (FR), (affiliate of Lhoist Group)

E-mail: co2team@lhoist.com

Beneficiaries:

Air Liquide France Industrie (FR)

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the granting authority, the European Climate, Infrastructure and Environment Executive Agency (CINEA). Neither the European Union nor the granting authority can be held responsible for them.