Fluidized Bed Boiler (FBB)

What is the Fluidized Bed Boiler (FBB) process?

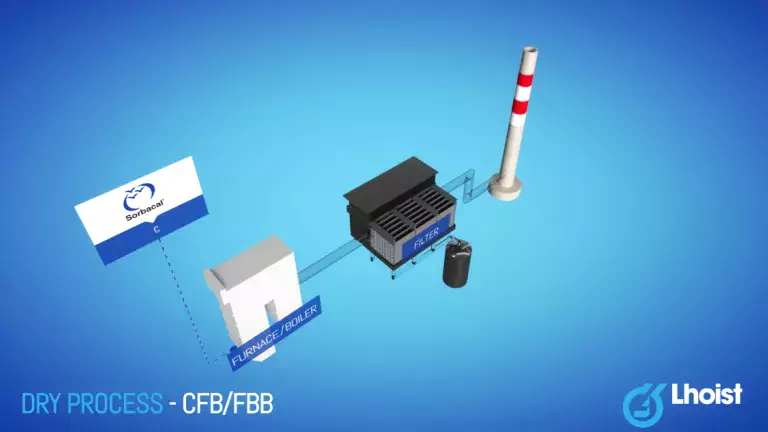

In a circulating fluidized bed (CFB) or fluidized bed boiler (FBB), the fuel particles are suspended in a hot (800-900°C) bed of fluidized solid materials: fuel, sand, ashes, and so on. Air is blown through this bed to keep it fluidized and to provide the necessary oxygen for combustion. When limestone CaCO3 is added to the hot bed, it decomposes, resulting in selective SO2 removal similar to the FSI process.

On-site removal of SO2 is an easy and effective solution for SO2 control in plants operating CFB/FBB technologies. When coupled with a downstream FGT installation, it enables the pre-treatment of heavy SO2-loaded gases.

Lhoist product range dedicated to CFB & FBB

Lhoist has developed a range of Sorbacal® C limestone products with grain size distributions that are adapted to the specific flow conditions of different CFB/FBB combustion technologies. Mixing this with the fuel ensures a longer residence time for the limestone particles in the fluidized bed, thus improving the performance of the on-site SO2 removal.

- Sorbacal® C