EVEREST

Summary

The objective of the EVEREST project is to (almost) completely decarbonize Europe's largest lime plant, located in Wülfrath, Germany.

The project would construct a completely new type of lime kiln and a large-scale industrial separation plant, which would allow CO2 to be captured and stored, both permanently and safely. Air Liquide, a leading global industrial gas specialist with a proven technology for CO2 capture, is the project partner for the construction and operation of the capture plant. The project plans to achieve 89% relative greenhouse gas (GHG) emission avoidance compared to the reference scenario.

Flandersbach

Germany

2024

starting date

2029

planned date of entry into operation

Advancing Carbon Capture and Full CO2 Value Chain

This innovative project would cover the full CO2 value chain from an inland lime plant: capture, liquefaction, pipeline transport, shipping, and offshore geological storage. It would bring together all the elements of the carbon capture and storage (CCS) chain, solving potential interface issues and demonstrating the full value chain for the first time on an inland lime plant.

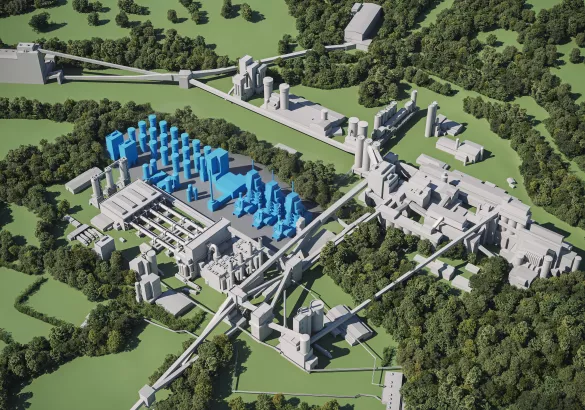

Simplified illustration of the Everest project, which aims to build state-of-the-art

lime kilns and a large-scale industrial CO2 capture plant.

For the carbon capture aspect of the project, a CO2 capturing unit dedicated to flue gas treatment would be connected to a combination of rotary kilns and parallel flow regenerating kilns (PFRK). Technology partner Air Liquide would build the first Cryocap™ FG unit in a lime plant at an industrial scale. The Cryocap™ technology uses cryogenic temperatures to separate gases and creates a 99.99% pure CO2 stream needed for CO2 transport and geological storage. Moreover, new PFRK Oxyfuel kilns would be built with a specialised technology to capture the CO2 from these types of kilns which is already highly concentrated. This technology has the potential of wider impact in the sector, since PFRKs are the most commonly used kiln type in the lime industry worldwide.

The project is expected to significantly raise the technology readiness level of the key technologies being used, particularly for existing kilns. The fully developed project aims to avoid, through capture and storage, absolute greenhouse gas (GHG) emissions of up to 9.3 million tonnes of CO2 equivalent over the first ten years of operation.

The CO2 avoidance figures in detail

Everest aims to capture in sum up to 1.4 million tons of CO2 per year. The CO2 would be captured both on the existing kilns and the newly build PFRK with oxyfuel technology.

Together with the planned switch to lower-emission fuels a total of almost 1.6 million tons of CO2 per year can be abated if compared to the current production method.

Compared to per capita emissions, this is roughly equivalent to the CO2 emissions of over 220,000 people in Germany*.

The European Union's funding scheme for the project uses a reference production plant as a theoretical benchmark. Compared to this reference production plant, the project will save 9.3 million tons of GHG over the course of 10 years.

*CO2 per capita emissions in Germany in 2022 according to the European Commission's JRC report from 2023 (https://edgar.jrc.ec.europa.eu/)

With the EVEREST project, we are leading industrial lime production into a climate-neutral future.

Behind the technology

The lime industry is one of the “hard-to-abate” industries, as lime production generates CO2 from the decomposition of limestone. These so-called “process emissions” cannot be avoided by switching to zero-carbon fuels.

This first-of-its-kind project would support local and other European lime users from various industries, such as water treatment, chemicals, paper, and steel manufacturing, in their path to carbon neutrality, by providing low-carbon lime on the market. Leveraging its know-how and unique expertise in CO2 capture technologies, Air Liquide would build and operate a unit of its innovative and proprietary Cryocap™ FG (Flue Gas) and Cryocap™ Oxy technologies which are 100% electrical and would help to decarbonize the lime sector in Europe.

Contribution to EU Climate Neutrality

The project would contribute to the European goals of promoting carbon capture and storage technologies, such as the objective of the Net-Zero Industry Act of achieving 50 megatonnes (Mt)/y CO2 storage capacity by 2030. Throughout its lifetime, EVEREST would share its experiences to support other industries in their efforts to contribute to the EU's objective of achieving climate neutrality by 2050 and would be instrumental to create CO2 supply chains and a new CO2 economy.

A socio-economic impact

The project would also create potential socio economic impact, planning to create 40 direct jobs and 500 indirect jobs. EVEREST shows a high scalability potential on existing plants both at sector level (cement and lime industry), and on an economy-wide level across sectors and across countries, tackling one key "difficult-to-abate" sector. Due to its sheer size, EVEREST would be a nucleus for the CO2 infrastructure that is needed in Europe and would help other CO2 emitters within and outside the lime industry to develop and establish their own CCS projects.

" Since 1889, we have been extracting and processing millions of tonnes of limestone to produce mineral solutions that are indispensable for the functioning of modern industry and society. We have always done this reliably and in the highest quality - but above all with pronounced passion and foresight. Our goal is clear: as the largest lime producer in Germany and Europe, we will continue to make our contribution to the transformation of Europe. Because lime is a crucial raw material for building our future. "

Vice President & General Manager Lhoist Germany

Contact

Coordinator:

Rheinkalk GMBH (Germany)

everest@lhoist.com

Beneficiaries:

- Rheinkalk GmbH

- Air Liquide Deutschland GmbH (Germany)

- Air Liquide Global E&C Solutions France

- Air Liquide Global E&C Solutions Germany

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the granting authority, the European Climate, Infrastructure and Environment Executive Agency (CINEA). Neither the European Union nor the granting authority can be held responsible for them.